Are Special Sockets Required for Impact Drivers?

Impact drivers are powerful tools that are commonly used in construction and automotive industries. They are designed to deliver high torque and fast rotational speed, making them ideal for driving screws and bolts into tough materials. However, due to their intense power, impact drivers require special sockets to handle the force and torque they produce.

Regular sockets, which are commonly used with hand tools such as wrenches and ratchets, are not suitable for use with impact drivers. The high torque and impact force generated by an impact driver can cause regular sockets to break, deform, or shatter, leading to potential damage or injury.

Why Regular Sockets Are Not Suitable

The main reason regular sockets are not recommended for use with impact drivers is their inability to withstand the intense force and torque produced by these tools. Regular sockets are typically made from softer materials and have thinner walls, which makes them susceptible to damage when used with impact drivers.

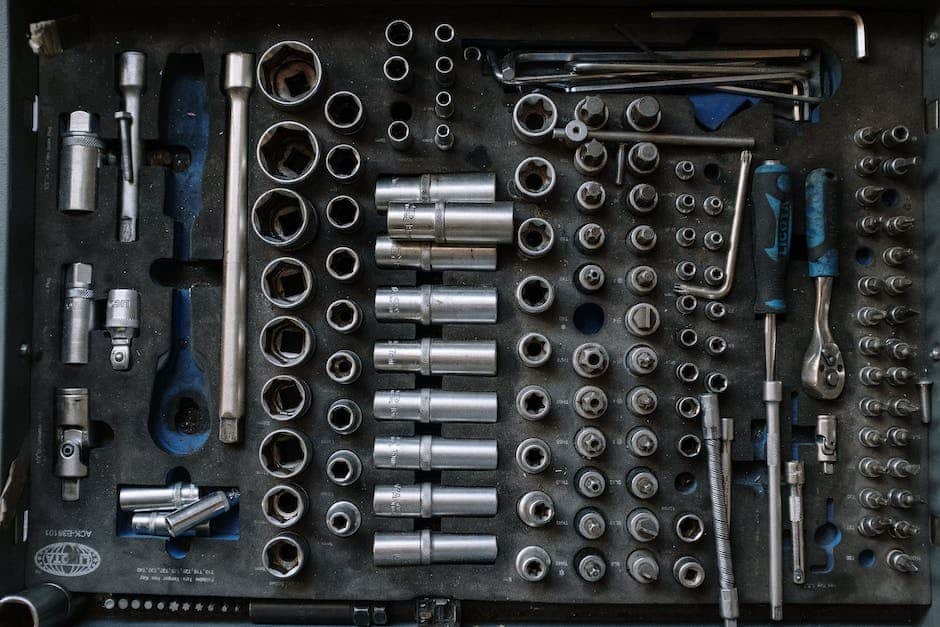

Regular sockets are typically made from chrome vanadium steel, which is strong and durable for use with hand tools. However, impact drivers require sockets made from even harder and more durable materials to handle the force and torque they generate. Impact sockets, on the other hand, are made from high-quality steel alloys that are specifically designed to withstand the high impact and torque of impact drivers.

The Benefits of Impact Sockets

Impact sockets offer several benefits compared to regular sockets when used with impact drivers:

- Durability: Impact sockets are made from high-quality steel alloys that can withstand the intense force and torque produced by impact drivers. Their thicker walls and specialized construction ensure they can handle the demands of impact driver use without breaking or deforming.

- Safety: Using the correct impact sockets reduces the risk of socket failure, which can lead to damage to both the tool and the socket, as well as potential injury to the user. Impact sockets provide a secure grip on the fastener, preventing slippage and potential accidents.

- Efficiency: Impact sockets are designed to transfer more torque from the impact driver to the fastener, resulting in faster and more efficient work. Their specialized construction allows for better power transmission, improving productivity and reducing the strain on the impact driver.

Using Regular Sockets with Impact Drivers

While it is strongly recommended to use impact sockets with impact drivers, some users may wonder if regular sockets can be used in certain situations. It is possible to use regular sockets with impact drivers if they are the correct size and securely attached to the impact driver using an adapter.

However, it is important to note that using regular sockets with impact drivers carries a higher risk of socket failure and potential damage to the tool and socket. The adapter used to attach the regular socket to the impact driver may not provide the same level of durability as impact sockets, increasing the chances of breakage or deformation.

In Conclusion

Special sockets, known as impact sockets, are required for use with impact drivers. These sockets are specifically designed to withstand the high torque and impact force produced by impact drivers, ensuring a secure grip on the fastener and preventing damage to both the tool and the socket.

While it is possible to use regular sockets with impact drivers by using an adapter, this carries a higher risk of socket failure and potential damage to the tool and socket. It is highly recommended to use impact sockets for optimal performance, efficiency, and safety when using impact drivers.

Related Websites:

FAQs:

Q: What is the purpose of an impact driver?

An impact driver is designed for driving screws and fasteners quickly and efficiently. It provides high torque and rotational force, making it suitable for heavy-duty tasks such as construction and woodworking.

Q: What are the advantages of using an impact driver over traditional drills?

Impact drivers have several advantages over traditional drills. They offer increased power and torque, making them more effective for driving long screws and fasteners. They also have a compact design, allowing for better maneuverability in tight spaces.

Q: Can I use regular sockets with an impact driver?

No, regular sockets should not be used with an impact driver. Impact drivers exert a high amount of force, and regular sockets are not designed to withstand that force. Using regular sockets can lead to socket breakage and potential accidents.

Q: Why should I use impact-rated sockets?

Impact-rated sockets are specifically designed to withstand the high torque and force generated by impact drivers. They are made from stronger materials and have a reinforced construction, reducing the risk of socket breakage and ensuring safer use.

Q: What should I consider when choosing impact driver sockets?

When selecting impact driver sockets, it is important to consider the correct socket size for your specific impact driver model. Additionally, ensure that the sockets are impact-rated and compatible with your impact driver brand to ensure optimal performance and safety.