Are you looking for the best bandsaw blade available in the market for resawing? If you are, then you’ve come to the right place.

The term ‘resawing’ can make you wonder about the purpose of sawing the same wood repeatedly. The purpose definitely exists. Resawing is the process in which you split the thickness of a piece of wood to produce thinner slabs. What you actually do is slice timber along the grain direction to make veneers or narrow sections.

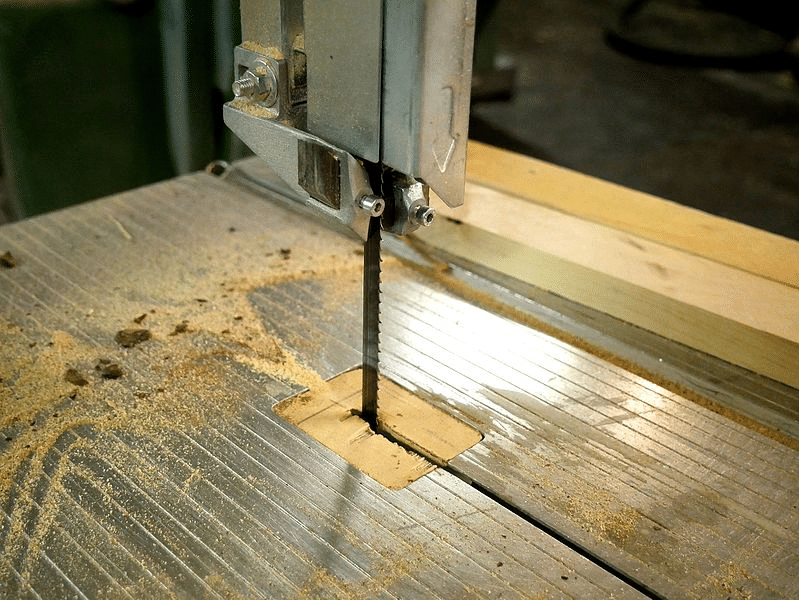

You can resaw manually using a hacksaw or make use of electronic machines like sawmills or bandsaws.

When it comes to using power tools for resawing, bandsaws are one of the most popular ones among woodworkers. The biggest benefit of using one is that it can resaw lumber that is wider in size.

Think bandsaw blades allow you to save wood, making it a cost-effective process for you. With bandsaws, the cut is finalized in a single go which results in cleaner, sharper edges. The blade guide on them can be raised to accommodate wider boards and they are way safer than table saws.

Here are some things to consider when choosing a bandsaw blade for resawing:

Bandsaw Blade Width

- While resawing, it is recommended to use the maximum blade width to keep the cuts clean and straight.

- While contour sawing, using a narrow blade is recommended which is sufficient for cutting the desired radius.

Bandsaw Blade Thickness

- A thick bandsaw blade is essential so that it can tolerate flex, heat, and cold which will prevent metal fatigue. The thicker the blade, the more it can withstand the cutting strain. At the same time, it would easily break and twist.

- A thinner blade would be optimum for lighter woodwork.

Number of Teeth Per Inch

- The blades that have more teeth cut at a slower rate but produce smoother results.

- The bandsaw blades consist of lesser teeth cut at a quicker pace but the finalized texture is quite rough.

- For precision and accuracy, it is essential to keep at least 3 teeth in the material (whether it is wood or metal) while you make your cut. This makes the cut more stable.

Tooth Styles and Sets

Bandsaw blades have the following 3 basic tooth styles:

- Regular Tooth Blades: These blades have teeth with equal spacing between them. They are ideal for multipurpose cutting and contour sawing. They are most suitable for cutting thin materials that have a finer finish.

- Skip Tooth Blades: These blades have teeth with wide spaces in between and the teeth are placed at a 0-degree rake angle to prevent any sort of clogging problems from occurring when cutting softwood, plastics, and non-ferrous plastics.

- Hook Tooth Blades: With teeth relatively larger and placed at a positive ten-degree rake angle, these blades are ideal for more aggressive applications and cutting at a faster rate. They are conventionally used for longer cuts in wider wood, hardwood, metal, and plastic.

Using a dedicated resawing blade and tuning the bandsaw correctly is essential to get clean edges and thus the best results. However, you’ll first need to purchase a bandsaw blade that can handle all the demands of resawing. Choosing the best equipment for your hefty tasks can be overwhelming, especially when there are so many various manufacturers and models to choose from.

To make this decision less confusing for you, we’ve conducted research, taken a look at the best products available in the market, carried out the necessary comparisons, and come up with a list to assist you. Here is a list of our picks for the best bandsaw blades for resawing:

Olson Saw FB23193DB

- The product is easy installation and easy handling

- The product is manufactured in China

- The product is easy to use and highly durable

- For hard or soft wood, plastic, mild steel and non-ferrous metal

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

If you are just getting started as a woodworker and are on a tight budget, Olson Saw FB23193DB is one of the best options for you. This blade is a multitasker as its ranker set contains the ability to rotate it right, left, and straight. It is extremely easy and simple to install and handle which makes it beginner-friendly.

Whether it’s woodworkers, professional Craftsmen, or DIY types, this product is made for everyone. It can easily power through hard or softwood, plastic, mild steel, and non-ferrous metal.

What helps this blade stand out is its hooked angled teeth that can carry more shorn material out of the grove as you make your cuts and keep your cut sight clear without having to stop and manually clear out the space. It has three teeth per inch which make it perfect for resawing and deep gauge cutting.

MK Morse 1182-MKM

- Made in the USA

- Shock resistant cutting edge for cutting any machinable metal

- Variable tooth pitch for broader range of applications

- Reduced vibration for improved cut finish and cutting fatigue

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Known for its portability, strength, and integrated dual-edge made from Bi-metal Cobalt, MK Morse 1182-MKM is highly durable and gives you great precision and accuracy when cutting different materials. It has high wear and heat resistance and is compatible with most materials including Stainless Steel, Aluminum, Carbon Steel, and Plastic. It also has variable pitch teeth which result in anti-vibration operation providing higher precision during operation.

It comes with raker-style teeth which means it has no chip sticking issues and has 14 to 18 TPI. It can be used on medium to heavy production machines to cut solids and heavy-walled structures and can handle materials that are quite hard to work with like stainless steel, Inconel, and Monel.

Timber Wolf Bandsaw Blade

- 935-3403PC: 93.5 long x 3/4 wide x 3TPI in Positive Claw (PC) tooth style

- Other Blade Specifications: .056 kerf; 6.5 degree tooth angle; 5-7/16 cut radius

- Cutting Application: resawing kiln dry domestic wood

- Suitable Material Thickness: kiln dry hardwood 3 - 12; softwood 3 - 12; green hardwood 3 - 12; green softwood 3 - 12

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Whether you want to make quick rip cuts or need precision while cutting contours, timber wolf blade can do it all. The blade is made from low carbide steel and has silicone-coated teeth and a thin kerf. It is a low-tension blade, which means it does not put too much pressure on the balls and bearings of your band saw. This means your saw will need a lot less maintenance over time.

With this blade, you get smooth, precise, and thin cuts in large stocks of hardwood because of its unique five-set tooth pattern. This makes the blade extremely durable and productive even after hours of cutting.

The blade is ½ “ in width and works best with 14” bandsaws. The thin blade is great at dissipating the heat away from the teeth which makes it less susceptible to bending under greater stress.

POWERTEC 13117

- Includes: 93 ½ inch band saw blade (one piece) – suitable for most 93-1/2” long, 3/16” wide, 0. 025” thick, band saw blades

- Quality: the band saw blade is made from premium, high grade carbon steel with heat resistance and weld

- Design: This precision cutting tool is constructed with an optimal geometric tooth arrangement that provides seamless cutting results at high performance speeds

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Made from high-grade Carbon Steel, POWERTEC 13117 is a reliable and durable blade. Its raker set teeth are great at getting rid of the excess debris by scooping it away from the blade. Resulting in less friction and heat and preserving the teeth for much longer. The blade produces neat cuts when working with softwood, aluminum, plastics, and non-ferrous metals as it is a 10TPI blade.

The carbon steel build gives this blade an extremely sharp cutting edge that won’t become dull quickly. It is also quite flexible which makes it quite useful when cutting at difficult angles. Moreover, it is a lot less expensive when compared to similar counterparts.

Although this blade is good enough to power through hardwood with ease, to prolong its life it is better to stick to softwood. If you do want to use it to cut hardwood, the blade will need sharpening after a while, but it shouldn’t affect the overall performance of the blade.

Milwaukee 48-39-0539

- Blade Dimensions 35-3/8 x 1/2 x .020

- TPI/Grit 24 TPI

- Includes: (3) 24 TPI Standard / Deep Cut Portable Band Saw Bla

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Made with alloy backing steel, this compact bandsaw blade has matrix II high-speed steel teeth that are capable of powering through a wide variety of materials including strut, conduit, angle iron, copper tube, threaded rod, and pipe. Its versatile design allows it to cut common materials 5/32″ thick.

Its precision teeth provide precision, accuracy, and fast cutting and make it extremely durable when cutting through hard materials. The blade is 35-3/8 in Length and ½ “ in width, while the thickness is 0.02 “. It is a 24 TPI blade with wavy teeth, HSS Cutting Edge, and a Bi-Metal Body. It works well with Non-Ferrous Soft Metal, Soft/Medium Steel, and Stainless Steel.