Whether you’re a handyman or a serious crafter, you probably have an impact gun (also known as an impact wrench) in your toolbox. Impact guns need to be connected to an air compressor to run, but obviously, if you’re doing a small job at home you won’t need an industrial air compressor.

Read on to find out what the basic requirements are for an air compressor and which kind is best for use with an impact gun.

Working with Compressed Air

Compressed air is a versatile form of energy that can be used for pretty much anything: auto repairs, renovations, construction and so on. Not only is it cost-effective, but you can even adjust the pressure of compressed air to use it with numerous pneumatic tools.

Air tools help you get the job done in half the time and with half the effort. An advantage of compressed air is that it doesn’t build up heat and there is no danger of experiencing an electric current.

What to Look at When Choosing a Compressor

Once you know exactly what to look for, it will become easy for you to select the right air compressor that works with your air gun.

Purpose

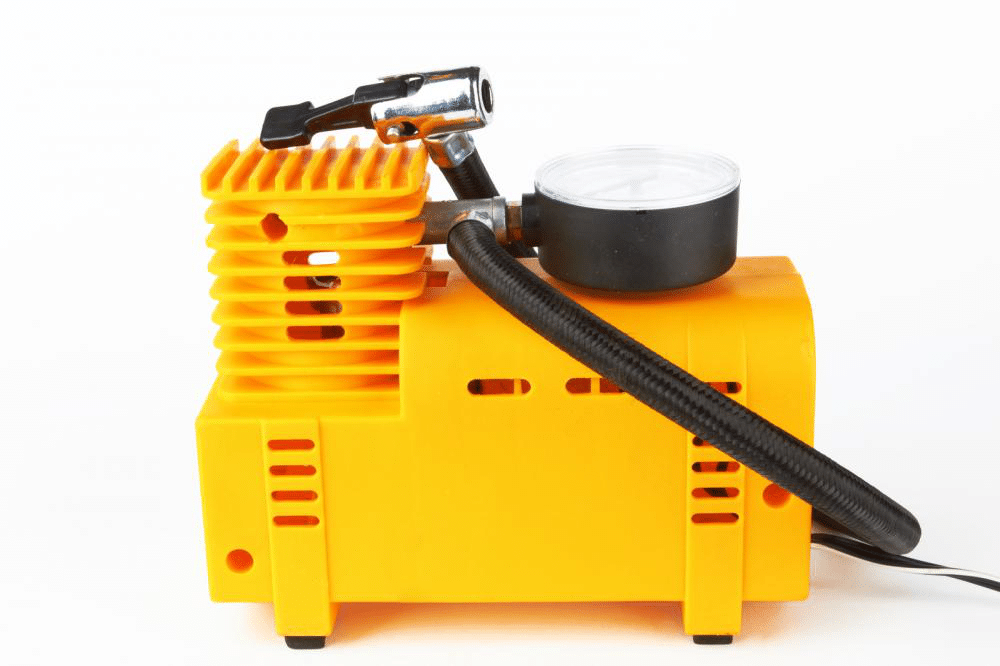

Compressors may be portable or need a power outlet to run.

The ones that require a power outlet are generally larger, heavier and generate a greater amount of power because they have a bigger tank. A tank with a high volume can store a greater amount of air. This air is then pumped through with a consistent CFM rate.

Portable compressors are smaller, lighter and easier to move around. With portable compressors, you have the advantage of accessing a power source on-the-go. In fact, portable ones are the preferred choice for use with an impact gun.

What is CFM?

CFM or Cubic Feet per Minute is a measure of the rate of airflow through an air compressor. The CFM value is particularly important for devices and machinery that require high CFM such as power saws, dryers, etc. other tools such as nail guns don’t need a constant flow of air. Sharp bursts of air can help get the job done and a low CFM is suitable.

To get a compressor for an impact gun, the core components to consider are the CFM value as well as the operating pressure of the compressor.

Power

The power of an air compressor is determined by its tank size and airflow.

Airflow

Airflow includes 2 factors: the CFM and the PSI (Pounds per square inch). The standard requirements for an impact gun are:

- For a 0.5 impact gun: 4.0 CFM & 90 PSI

- For a 0.75 impact gun: 5.0 CFM & 90 PSI

If you’re planning on using multiple types of impact guns with a single compressor, it is recommended to obtain a compressor with higher CFM and PSI values. This will ensure that your tools run at their full potential.

A general rule of thumb is that the compressor you select should have a CFM value that is 1.25-1.5 times more than the recommended value.

Single vs. Two-Stage Compressors

Single-stage compressors have a single pump to transfer compressed air from the tank to your tool. Standard single-stage pump compressors deliver around 155 PSI and have a CFM level below 100 PSI. Standard two-stage pump compressors deliver around 175 PSI and have a CFM level below 100 PSI.

For impact guns, a single-stage compressor is more than sufficient since they don’t require the twice-compressed air delivered by the two-stage pump.

Tank Size

Tools that require a continuous flow of air should be used with an air compressor with a large tank size. For smaller tools that need airflow in spurts (such as impact wrenches), a small tank size is sufficient. The tank should be capable of powering whatever tools you have. Your decision should not be based on which one is cheaper and easier to store.

Electric vs. Gas Powered Compressor

Gas-powered compressors are not meant for indoor use and are generally costlier than the electric ones. The maintenance charges are also higher since they run on oil instead of gas.

For air compressors being used with an impact gun, the electric ones are the better option.

Storage Space

Apart from the use, you also need to keep in mind how much space you have to store your air compressor. A 30-gallon tank is most probably not going to fit in your garage corner, but a 6-gallon one definitely will. Lucky for you, an impact gun can run on a small air compressor. Portable compressors are the preferred choice with impact guns.

Quality

A good quality air compressor will be durable and provide a consistent, solid CFM. The extra investment in a premium compressor brings advantages such as:

- Low heat output

- Constant power supply requiring you to put in less effort

- Reduced risk of a fire or electric current

- Durability

Price

Of course, good quality comes at a price. There are countless different types of compressors ranging anywhere between 30-3,000 USD including the high-powered options. A portable, small air compressor for an impact gun can easily fit within your budget. If you have room for the extra investment, you’re likely to end up with a device that can last for a good few years.

What Can You Do with an Air Gun?

Impact guns provide a high level of torque and are a handyman’s staple tool. They offer a number of advantages:

- They require very little time and effort as opposed to wrenches and other traditional tools.

- You can use an air gun to secure heavy objects together without worrying about any nuts and bolts coming loose later on.

- They can be used for multiple tasks such as fixing car tires, fixing the wooden paneling on your walls and even just to hang up some heavy artwork on the walls.

You’re Ready to Get Started

Once you know exactly what type of air compressor you need for your impact gun, you’re ready to start working. Whether you’re trying to drill a broken bolt out of your old washing machine or fixing the wooden deck on your patio, your job will require minimum time and effort if you choose the right air compressor.