If you are new to air compressor terms and are looking to increase your knowledge on the topic, learning how to increase CFM on an air compressor will help you take one step in the right direction.

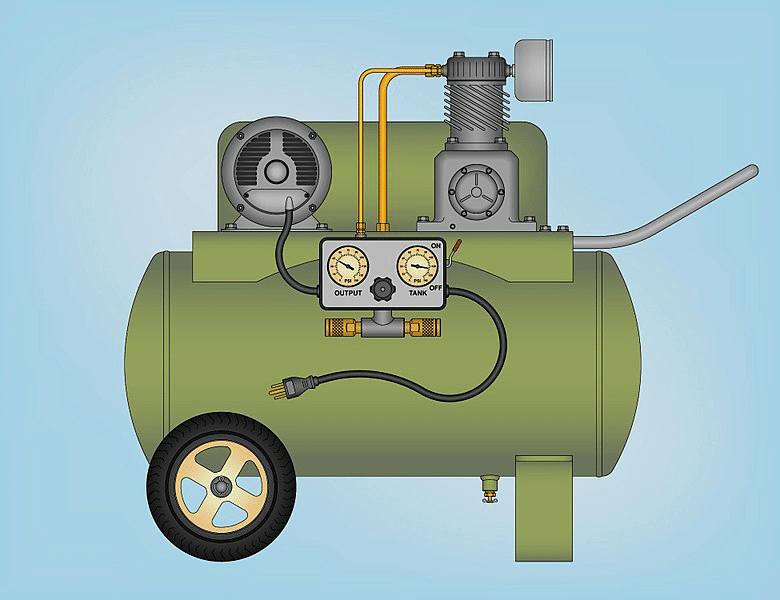

Air compressors are popular for their versatility. They can be used for a whole wide range of things such as to pump up your tires, color your walls, or even simply to use nail guns.

CFM, also widely written as cfm or even acfm i.e. average cfm, stands for cubic feet per minute. It is a measure of the flow rate of the air that gets thrown out by a compressor. The relation between the two is extremely important as CFM is directly related to the suitability of an air compressor for a specific application.

Importance of CFM

CFM is an essential factor when it comes to determining the effectiveness of an air compressor. Since no air is flowing into the compressor, no air pressure will be generated; as a result, your tools won’t work. Some tools such as saws or pressure washers have unlimited demands and require a higher cfm.

On the other hand, appliances like nail guns might need a very short and sharp burst of air and that too occasionally. In this case, a lower cfm can be acceptable.

Now, that we’ve established that higher cfm ensures higher output and lets you accomplish bigger tasks, the real dilemma is increasing it.

How to Increase CFM on an Air Compressor?

One method to increase the cfm on your air compressor is purchasing another air compressor and hooking the two of them together. This allows you to increase the cfm more than the maximum capacity of the compressor by taking additional help from a different device.

Most of the air compressors that are available online come with different maximum PSI, making some tools less suitable for some compressors than others. Know exactly the kind of air compressor will be suitable for you before going ahead and purchasing it.

One drawback to this method is that sometimes it might take longer to entirely fill the air in both the tanks. The longer this process’s duration, the more chances there are of your compressor overheating; this can lead to other serious maintenance problems.

You don’t want your tool to malfunction when you’re in the middle of a project; therefore, in this case, you can go for the second option which is to increase the cfm of your air compressor is by providing the execution of the whole operation some extra time. This way, the compressor becomes capable of keeping the tank pressure up.

To accomplish this, all you need to do is dial the regulator down at its lowest setting possible in which the tool is capable of operating. This allows the air compressor to run for a long period and hence, you can use your tool the way you like. If your tool starts working perfectly, then you might have some more room to dial the regulator setting down.

The second method comes with great benefits for your compressor, as it prolongs its life and gives it extra time to get filled back up while it is being used side by side.

Can The CFM Be Decreased?

Yes, the cfm on an air compressor can indeed be decreased. If you don’t want a lot of air rushing into the compressor at once, you can easily decrease the cfm. It is important that you do so carefully, as decreasing the cfm too much can cause your tools to fail from working.

Many times, the actual rate of an air compressor is misrepresented on the label of the product by manufacturers. To increase and decrease the cfm on your air compressor, you should be able to calculate the exact amount of air that you are pumping.

How to Calculate CFM of Your Air Compressor

Calculate the true cfm of your air compressor with the following few simple steps:

Step 1

Start with determining the total volume of your compressor tank. Measure the volume in gallons. You can either measure it yourself or look at the label on the tank provided by the manufacturer.

Step 2

One cubic foot contains 7.48 gallons; therefore, divide the tank volume by the same amount. This will give you the volume of your air compressor tank in cubic feet.

Step 3

Now, release all the air from the compressor.

Step 4

Start refilling the compressor tank with air. Pay close attention to the gauge of the compressor tank and record the exact amount of time that you need to entirely refill the tank. Now, record the pounds per square inch (psi) at two different points of time during the air refill process; first, at the time that the compressor kicks in and later, at the time when it kicks out.

Step 5

Now calculate the difference between the psi that was indicated on the compressor tank’s gauge when the compressor kicked out and the psi indicated when it kicked in. For instance, if the air compressor kicks out at 115 psi and kicks in at 95 psi, then the difference would be of 20 psi.

Step 6

Once you’ve calculated the difference, simply divide it by 14.7. The calculated number will be the amount of air pressure in terms of atm (atmospheric pressure) added during the filling cycle of the air compressor tank.

Step 7

Take the volume of the tank in cubic feet that you calculated in the second step and multiply it by the amount of air pressure expressed in atm (atmospheric pressure) that you calculate in the sixth step. This will give you the total number of cubic feet that is pumped by your air compressor in the time taken by your tank to fully fill (calculated in the fourth step).

Step 8

Now, take the cubic feet number you calculated in the last step and divide it by the total number of seconds it took you to pump this amount of air.

Step 9

For the last and final step, multiply the result by sixty. You have now successfully calculated the cfm of your air compressor.

If you are looking to buy an air compressor, make sure you know how much power, size, and CFM you will require. The more your cfm goes up, the lower your PSI may go down. It is essential to figure out what you’re purchasing an air compressor for. This will allow you to decide and adjust your cfm requirements accordingly!